Create a resilient SCM framework that proactively responds to volatility in costs and supply.

- Gartner client? Log in for personalized search results.

Supply Chain Management (SCM): What, Why and How

Minimize complexity to meet the relentless demand for more capacity

More than 60% of supply chain leaders say the supply chain management (SCM) process is responsible for escalating costs and risks. And it's about to go from bad to worse: Over half expect SCM to become more complex over the next five years. Download this guide to learn:

The main supply chain challenges that create the most complexity

How to better manage said complexity using lifecycle orchestration

5 key strategies for evolving the SCM process to prioritize innovation, resilience, and agility

How to approach SCM in a persistently disruptive environment

Crises like pandemics and wars expose the global supply chain’s weaknesses. Embed resilience in supply chain management to ensure the system can function under stress and bounce back from disruption.

- Future SCM Strategy

- Digital Ecosystems

- Agile SCM

- SCM Cost Savings

- SCM Metrics

To create value, supply chain managers must evolve the operating model

Supply chains have always been complex — with thousands of suppliers, partners and products spanning a footprint with hundreds of sites and markets. But supply chain complexity is constantly growing, wreaking havoc with the ability to implement change, service level, reliability and customer satisfaction. It’s critical that supply chain leaders evolve supply chain management strategy to address persistent disruption. The project-based continuous improvement and transformation approaches we’ve traditionally used won’t work. We must experiment, pivot, scale and abandon new concepts to ensure effective SCM.

Complexity is not wholly “bad.” Though it challenges execution, it also enables SCM value.

Supply chain complexity expands organizational capabilities: Though 53% of supply chain leaders say supply chain complexity reduces their ability to implement change, 47% say it also enhances their ability to innovate.

Supply chain complexity accelerates disruption handling: 41% of supply chain leaders say complexity in the SCM process is what drives resilience and agility in the operating model.

To tame complexity — i.e., minimize complexity where possible and ensure that the benefits of required complexity outweigh the negatives — the leading global chief supply chain officers are managing the life cycle of each aspect of the supply chain operating model (capabilities, technology, sites and partners). In this way, they create the space and resources to innovate SCM strategy.

Tactics for taming complexity in SCM strategy

Tactic 1. Supply chain leaders are typically hesitant to end the use of a process or technology, which means complexity is added to the supply chain but never taken out. Gartner recommends establishing formal policies for retiring processes/technologies and regularly conducting reviews to assess process/technology fitness.

Tactic 2. Supply chain leaders don’t know when to allow or restrict sources of complexity because it’s hard to identify and embrace the complexity that actually improves competitive position. The solution: building supply chain planning capabilities like customer needs analysis, segmentation, formal competitive assessments, and risk discussions.

Tactic 3. Traditionally rigid operating model design principles limit the supply chain’s ability to handle complexity. Composability in the operating model, however, helps supply chain leaders structure complexity and make the changes that meet needs faster, more easily and more cheaply.

Tactic 4. Volatility and uncertainty add costs to traditional operating models, making it critical for supply chain leaders to take full advantage of cost-saving opportunities offered by ecosystem partners and technology.

Tactic 5. It’s hard for supply chain professionals to consistently adhere to process and policy guidelines, so it’s important that supply chain leaders capture the voice of the user to identify both roadblocks and opportunities to improve process flexibility.

Ecosystems improve SCM by connecting trading partners to a common data platform

Today the top three trading partners supply chain leaders interact with are Tier 1 suppliers, 3PLs and technology vendors.

But to have effective supply chain management in the future, leaders need to engage the broader trading network, which includes startups, government agencies and even competitors. According to Gartner research, by next year, the top three trading partners supply chain leaders will interact with will be Tier 2 and beyond suppliers, end customers/consumers and contract manufacturers.

The shift toward Tier 2 and beyond suppliers is particularly significant. The number of supply chain leaders engaging this group come 2025 will be more than double what it was just three years ago. And the shift away from engaging with Tier 1 suppliers and 3PLs is also remarkable. The number of supply chain leaders engaging these groups come 2025 will be less than half of what it is today.

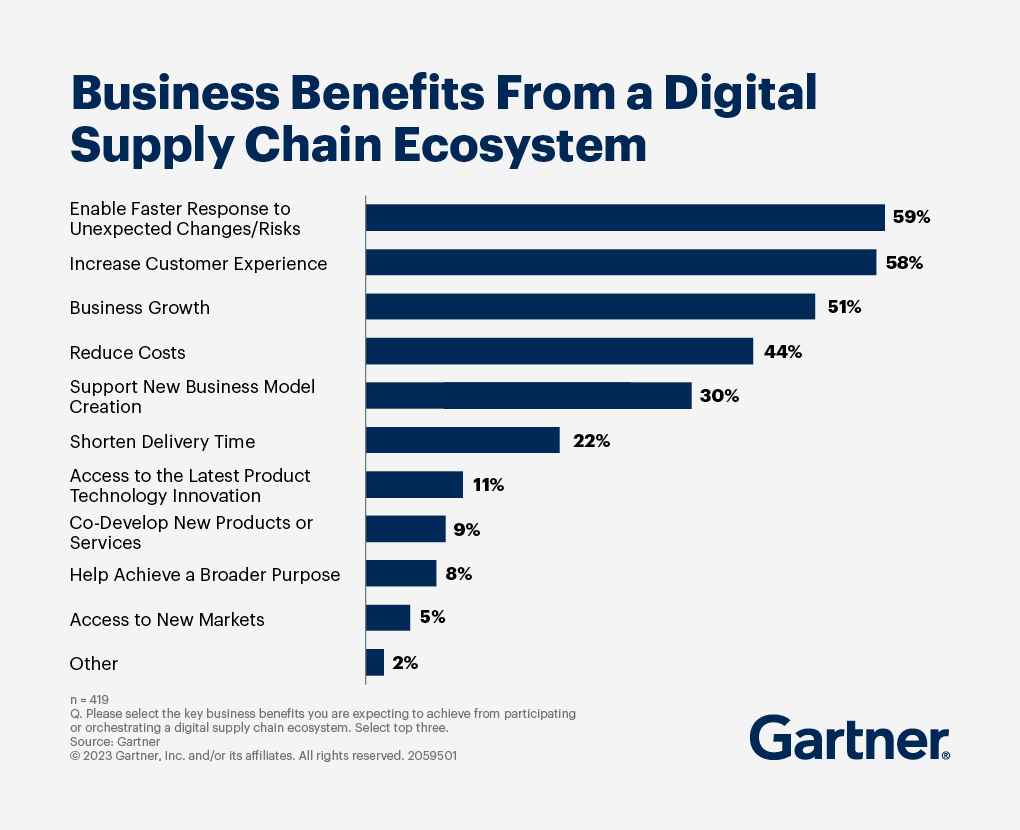

What do supply chain leaders expect to gain from engaging the broader trading network? At a high level, they expect a more cost-effective, end-to-end supply chain that supports new business model creation. More granular benefits include more effective supply chain risk management, enhanced customer experience, and business growth.

The key question is: How will supply chain leaders shift the supply chain strategy away from Tier 1 suppliers and 3PLs toward Tier 2 and beyond suppliers?

The answer is, by crafting a supply chain ecosystem in which every participant in the SCM process is connected through one common data platform. This includes all internal functions (e.g., R&D, procurement, manufacturing, logistics management, marketing, sales) as well as all trading partners (e.g., suppliers across tiers, 3PLs, customers). Rather than a linear chain, where data is transferred from one stage of the supply chain management process to the next, data in a supply chain ecosystem is readily available to all, providing near-real-time access to critical information, supporting informed decision making and enabling process execution across the network.

Over the next two years, more than 50% of chief supply chain officers (CSCOs) plan to invest in supply chain technologies and digital transformation because it greatly accelerates the creation of, and participation in, supply chain ecosystems. CSCOs must work with IT leaders to identify and adopt technologies that engage in real-time, secure data sharing and multienterprise process execution, as this will grow and scale the business value of the supply chain ecosystem.

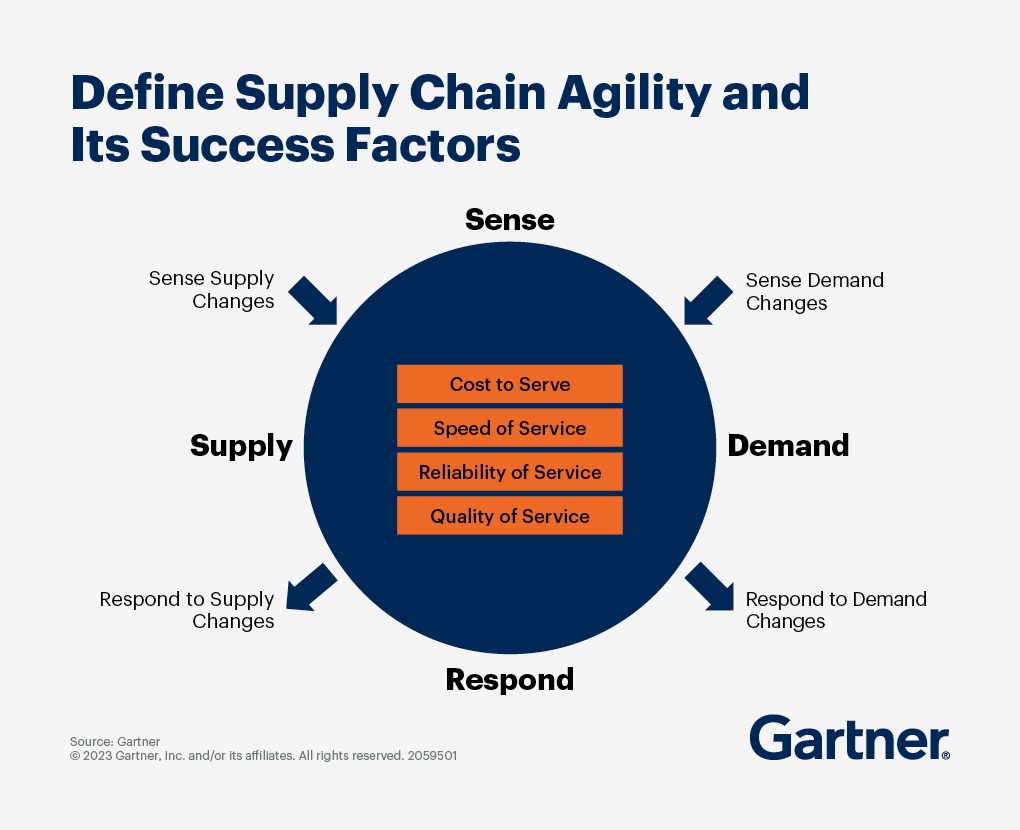

Agility in supply chain management means managing change and unexpected events

For over two decades, it was enough to operate an efficient supply chain. But in just the past few years, supply chain leaders have been beset by one disruption after another — including geopolitical instability, climate change events, energy scarcity and hybrid work — and thus the importance of agility and resilience in supply chain management has risen. Gartner research identifies agility and resilience in the supply chain management strategy as the two main priorities for almost all organizations.

But there is fear among supply chain leaders that prioritizing agility and resilience in supply chain strategy will increase supply chain costs. Over 30% refrain from investing in supply chain agility because they believe that agile supply chains are too costly to operate. Another 58% believe that resilience results in additional structural cost to the supply chain network.

Furthermore, unprecedented supply chain disruption has stretched supply management in ways few thought they would ever see. Modern global supply networks are complex, multitiered and often include highly specialized players that cannot be substituted easily. Global supply chain managers face myriad challenges, including global supply chain delays, capacity constraints, hyperinflation, material shortages, recession risk and new trade policies. Visibility into extended supply bases has generally been poor.

This is all an obstacle to effective supply chain management and creates a supply chain crisis for businesses across industries and across the globe. Only 21% of supply chain leaders believe they have a highly resilient supply chain management process today.

Explore top tactics for generating operating margin from supply chain management

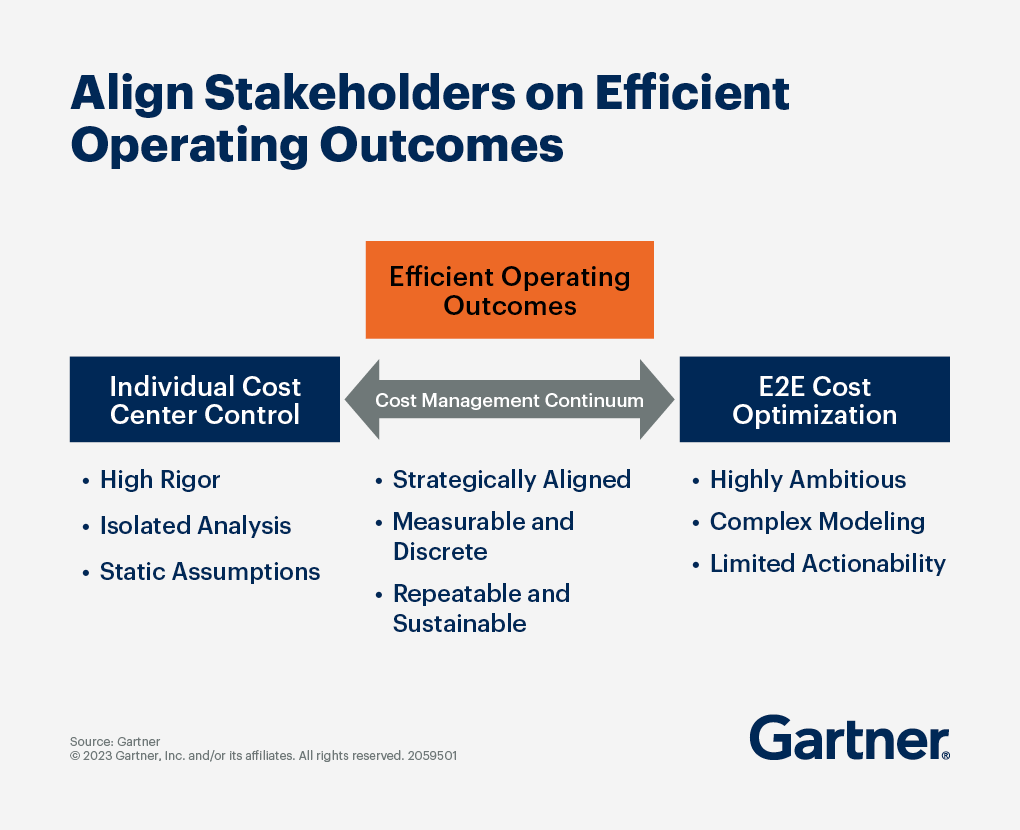

Balancing economic pressures with supply chain efficiency is no small feat. How can chief supply chain officers successfully navigate inflationary pressure, geopolitical escalation and energy constraints?

First, make near-term reductions to maximize operating cash flow from supply chain management. Then invest in optimized network performance to generate operating margin. The key is to maintain service delivery and operating efficiency, while controlling inventory levels. Engage key financial and commercial stakeholders in process design changes to increase capacity and capability investments. Ultimately, supply chain management must enable profitable growth.

Tactics for improving cash flow from SCM

Reduce duplicative roles and capitalize on low-cost locations.

Simplify SCM by centralizing end-to-end supply chain processes.

Patch time-consuming system inefficiencies with robotic process automation.

Audit software license distributions to improve demand planning.

Invest in artificial intelligence for spend analysis to identify opportunities for consolidation in spend data.

Eliminate wasteful and redundant supply chain logistics processes.

Invest in SCM software to help sourcing and procurement teams streamline processes, improve spend management and leverage extended supply networks.

Identify supply chain KPIs for improving supply chain management process

Establishing key performance indicators (KPIs) enables the supply chain organization to justify, monitor and improve processes by balancing local and global performance improvements. KPIs are not the end of analysis, rather the beginning of identifying an issue’s root cause and targeting corrective action.

Supply management metrics are the top-level objectives for the supply chain and typically consist of cost and service. The goal is to balance total delivered cost, customer service and sustainability.

But with these competing priorities, which KPIs should you focus on? How do you streamline the supply chain performance dashboard? To help supply chain leaders, Gartner has assembled this list of common supply management metrics.

SCM cost metrics

Standard costing includes total delivered cost, cost and profitability at the producer/customer level, and plan/actual versus budget. It should be combined with activity-based costing, which accounts for a lower level of cost granularity — the activity-driven costs behind much of the true supply chain cost. Only with true supply chain cost measured can an enterprise effectively make the necessary trade-offs between total cost and service.

Total cycle time is the total time for a product to pass through the supply chain, from start to finish. How you plan and flow products through the supply chain has a big impact on the true cost, and thereby the real profitability of a product, making total cycle time a good complement to the cost metric.

SCM customer service metrics

There are many different supply chain analytics strategies for measuring customer service, the most popular method being OTIF, or on-time-in-full deliveries, at the order or order-line level. It’s critical that the customer service metric relate to what is meaningful to the customer, so use external-facing measures, as well as internal measures such as OTIF, to derive a measure of competitive customer service.

SCM sustainability metrics

Increasingly, SCM metrics include sustainability metrics that relate to issues of environmental impact, renewable energy, pollution and waste, biodiversity and land use, climate change, and water use. Common metrics include: net-zero emissions, waste reduction, reuse and recycle approaches used, regenerative approaches used, and supply chain miles.

Experience Supply Chain conferences

Join your peers for the unveiling of the latest insights at Gartner conferences.

Related supply chain management resources

Gartner clients: Log in for a complete suite of actionable insights and tools on SCM.

FAQ on supply chain management

What is supply chain management?

Supply chain management refers to the function of creating and fulfilling demands for goods and services. To optimize the flow of products and services from sources of supply to customers, supply chain partners from across the supplier network must integrate, synchronize and orchestrate their processes, including supply chain planning, sourcing and procurement, manufacturing, distribution and transportation.

How does globalization impact supply chain management?

Global supply chain management is the set of business processes that enable a value chain to create and fulfill demand for goods and services globally. Today’s global supply networks are complex, multitiered and often include highly specialized players that cannot be substituted easily. To drive shareholder and customer value, you must make the supply chain transformations necessary for improving visibility into extended supply bases.

How do global supply chains stay resilient amid disruption?

A resilient supply chain can avoid, absorb and recover from supply chain disruptions and continue to operate under stress. Your approach to global supply chain management must balance risks and costs. To achieve supply chain resilience, Gartner recommends: optimizing product portfolio design; strengthening ecosystem partnerships; improving inventory management; and diversifying both sourcing and manufacturing networks (e.g., nearshoring).

What trends are shaping future supply chain management?

The future of supply chain will be characterized by digital expansion, solution selling and diverse customer expectations. Global supply chain management can contribute value amid volatility by making it easier, faster, safer and less costly for the business to evolve operations. Responding effectively to disruption and balancing cost-efficiency with resilience are key to the success of global supply chain management.

Why is sustainability key to supply chain management?

Supply chain sustainability is intentional action on energy transformation and decarbonization for strong environmental performance, as well as ESG workforce implications. Sustainability helps grow the business, mitigate supply chain risk and attract and retain next-generation talent. Enable sustainability in global supply chain management by: committing technology and people resources; considering sustainability in portfolio decision making; and integrating sustainability data into processes.